Discover World Class Manufacturing with the Best Flow Wrap Machine from China

In recent years, the demand for efficient packaging solutions has surged, driven by the rapid growth of the global food and consumer goods markets. According to industry reports, the global flow wrap machine market is projected to grow at a CAGR of 6.3%, reaching a value of approximately $4 billion by 2027. This growth reflects the increasing preference for automated and versatile packaging systems that enhance production efficiency and reduce operational costs.

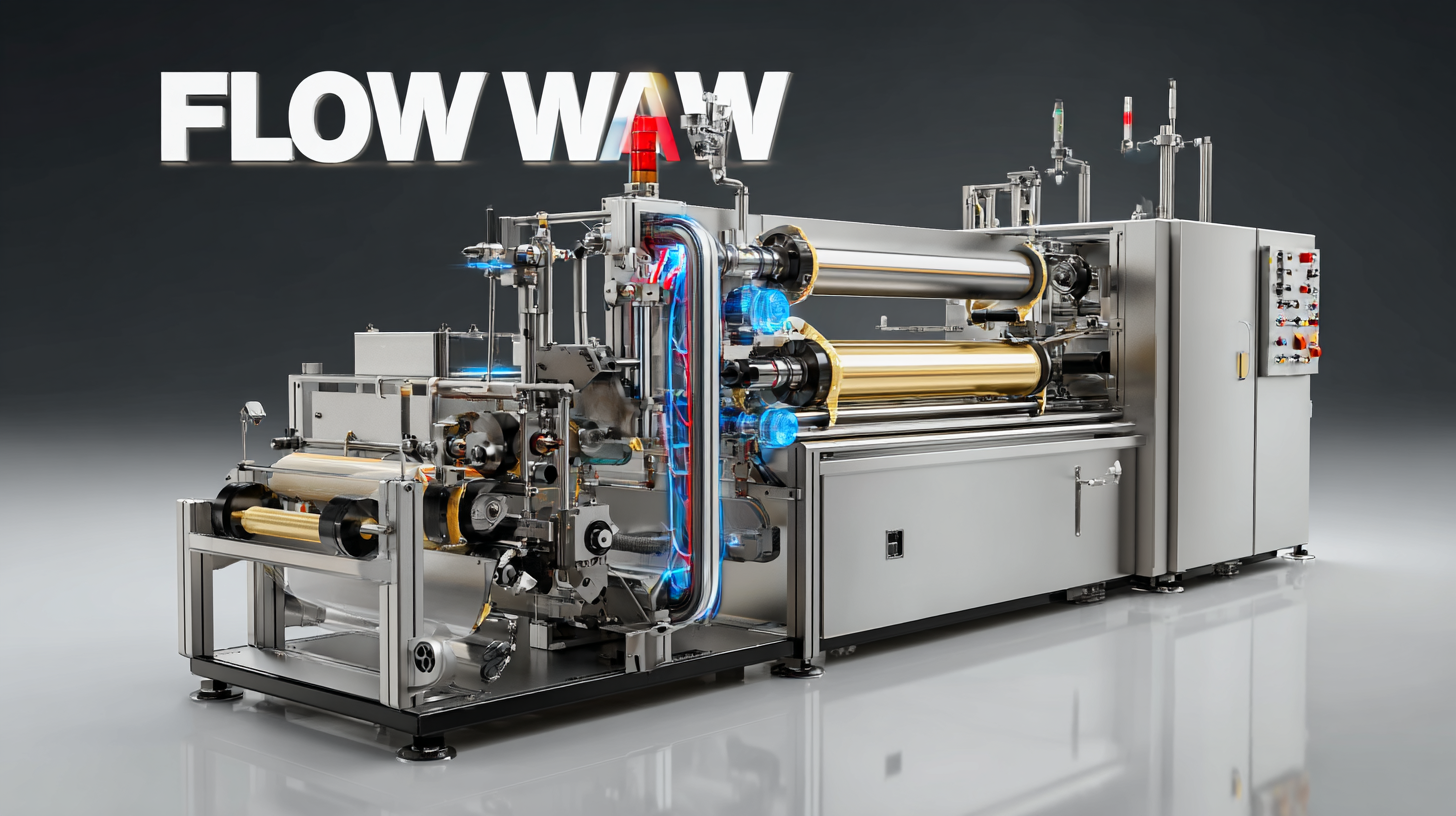

As a leader in manufacturing, China is at the forefront of this transformation, offering world-class flow wrap machines designed to meet diverse packaging needs across various sectors. With advanced technology and a commitment to quality, these machines not only improve packaging speed but also ensure product integrity, making China your ideal global partner for packaging solutions.

Discover how investing in high-quality flow wrap machines can elevate your manufacturing capabilities and help you stay competitive in an ever-evolving market.

Revolutionizing Packaging: The High Efficiency of Flow Wrap Machines

In today's fast-paced world, the packaging industry is undergoing a remarkable transformation, significantly driven by the high efficiency of flow wrap machines. These advanced machines streamline the packaging process, enabling faster production rates and reducing material waste, which is vital in today’s competitive marketplace. With their ability to provide secure and attractive packaging solutions, flow wrap machines are essential for businesses aiming to enhance their operational efficiency and overall output.

To maximize the benefits of flow wrap machines, consider these tips: First, ensure regular maintenance of your equipment to avoid unexpected downtime and maintain optimal performance. Moreover, invest in training for your workforce to ensure they utilize the technology to its fullest potential, which can lead to improved speed and accuracy in packaging operations. Lastly, continually monitor your packaging process with data analytics to identify areas for improvement, allowing you to stay ahead of industry trends and demands.

As we witness groundbreaking advancements in packaging technologies, including the integration of AI, the capabilities of flow wrap machines are set to redefine production standards. By focusing on high efficiency and innovative designs, these machines provide a competitive edge, making them indispensable in the quest for world-class manufacturing.

Top 5 Advantages of Choosing Flow Wrap Machines for Your Production Line

Flow wrap machines are becoming increasingly popular in production lines around the world, especially in China, where advanced technology meets high efficiency. Here are the top five advantages of choosing flow wrap machines for your manufacturing needs.

First and foremost, flow wrap machines offer unparalleled packaging speed. They can wrap hundreds of products per minute, ensuring that your production stays on schedule without compromising quality. Additionally, these machines are versatile and can handle a variety of products, from snacks to pharmaceuticals, making them suitable for various industries.

When selecting a flow wrap machine, consider investing in one with adjustable settings to accommodate different product sizes and packaging materials. This flexibility allows you to adapt quickly to market demands. Furthermore, regular maintenance is key to ensuring optimal performance; routine checks on the machine can prevent unexpected downtimes and costly repairs. By choosing the right flow wrap machine, you can boost your production efficiency and better serve your customers.

Why Chinese Flow Wrap Machines Are Leading the Global Market

Chinese flow wrap machines have emerged as leaders in the global market, revolutionizing packaging standards across various industries. Their advanced engineering design not only enhances efficiency but also ensures high-quality output, making them indispensable for manufacturers looking to optimize their production processes. With features like adjustable speed, versatile packaging sizes, and user-friendly interfaces, these machines cater to diverse packaging needs, from food products to pharmaceuticals.

One of the pivotal reasons for the dominance of Chinese flow wrap machines is their affordability without compromising quality. Manufacturers benefit from cost-effective solutions that enable them to invest in technology while keeping overheads low. Additionally, the robust supply chain and innovative advancements within the Chinese manufacturing sector allow for continuous improvements and faster production timelines. As a result, companies worldwide are increasingly turning to Chinese manufacturers for reliable and cutting-edge flow wrap machinery, setting new benchmarks in the packaging industry.

Discover World Class Manufacturing with the Best Flow Wrap Machine from China

| Feature | Specification | Benefits |

|---|---|---|

| Max Packaging Speed | 100 packs/min | Increases productivity and efficiency |

| Film Width | 300 - 600 mm | Versatile packaging options for various products |

| Power Consumption | 5 kW | Cost-effective operation |

| Control System | PLC with touch screen | User-friendly and precise control |

| Material compatibility | Plastic, Paper, Aluminum Foil | Flexible packaging for different products |

| Safety Features | Emergency stop, safety guards | Ensures operator safety during operation |

5 Key Features to Look for in a World-Class Flow Wrap Machine

When searching for a world-class flow wrap machine, one must consider several key features that define its efficiency and adaptability in manufacturing environments. First and foremost, speed plays a crucial role; a high-speed machine significantly increases productivity and ensures timely delivery of products. Machines equipped with advanced servo motors and control systems offer greater precision and can handle various packaging speeds, making them a valuable addition to any production line.

Another important aspect to consider is the versatility of the flow wrap machine. The ability to package a wide range of products, from food items to non-food goods, is essential for businesses looking to diversify their offerings. A top-notch machine should also come with adjustable settings for different product sizes and shapes, allowing manufacturers to switch easily between tasks without downtime. Additionally, durability and easy maintenance are critical. Machines built with high-quality materials and designed for straightforward servicing can save companies time and money in the long run.

The Economic Impact: Cost Savings and Increased Productivity with Flow Wrap Machines

The integration of flow wrap machines into manufacturing processes has led to significant economic benefits, particularly in cost savings and increased productivity. According to a report by the Freedonia Group, the global market for packaging machinery is expected to reach $60 billion by 2026, with flow wrap machines accounting for a considerable share due to their efficiency in packaging various products. These machines streamline operations, reducing labor costs by up to 30%, which is crucial for manufacturers seeking to enhance their bottom line.

Moreover, advancements in flow wrap technology have enabled manufacturers to boost production speeds by more than 20%. A study by PMMI (The Association for Packaging and Processing Technologies) found that companies utilizing automatic flow wrap machines can increase their output while maintaining high standards of product quality. This not only meets the rising consumer demands for packaged goods but also optimizes resource usage, contributing to a greener manufacturing approach. Investing in state-of-the-art flow wrap machines from China can thus render businesses more competitive in an ever-evolving market.