Exploring the Unique Features and Applications of the Best Form Fill Seal Machines: A Complete Guide

In the ever-evolving landscape of packaging technology, form fill seal machines stand out as a critical innovation. According to a report by MarketsandMarkets, the global form fill seal machine market is projected to reach USD 2.73 billion by 2025, growing at a CAGR of 4.5% from 2020 to 2025. These machines not only enhance packaging efficiency but also contribute significantly to reducing labor costs and improving product safety. With unique features tailored for diverse industries, including food and beverage, pharmaceuticals, and consumer goods, the best form fill seal machines are designed to meet specific needs while adhering to stringent regulatory standards. This complete guide will delve into the technical specifications and applications of these machines, providing insights on how to select the most suitable option for various packaging requirements.

Understanding the Basics: What Are Form Fill Seal Machines?

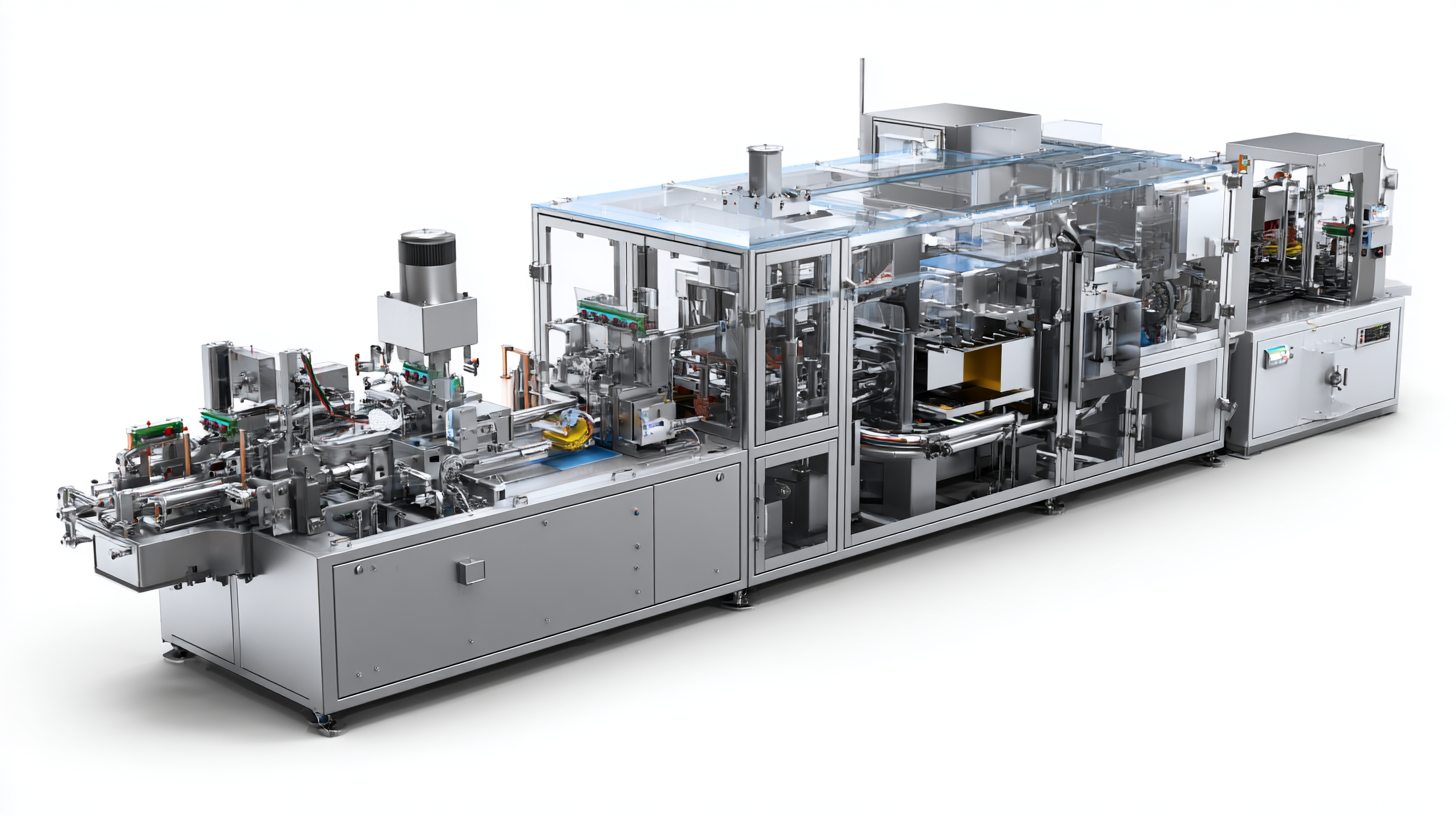

Form Fill Seal (FFS) machines are innovative packaging solutions that streamline the process of preparing products for distribution. Essentially, these machines take flat roll stock, form it into a pouch or container, fill it with the chosen product, and then seal it—all in one continuous operation. This method not only enhances efficiency by reducing the need for manual handling but also minimizes the risk of contamination, making it particularly advantageous for industries such as food, pharmaceuticals, and personal care.

One of the standout features of FFS machines is their versatility. They can accommodate a wide range of products, from solids and powders to liquids and pastes, making them an ideal choice for manufacturers with diverse packaging needs. Additionally, modern FFS machines are equipped with advanced technologies that allow for precise control over filling volumes and sealing processes, ensuring consistent quality and reducing waste. As demands for speed and sustainability in packaging continue to rise, understanding the mechanisms of form fill seal machines becomes essential for businesses looking to optimize their production workflows.

Exploring the Unique Features and Applications of the Best Form Fill Seal Machines

| Feature | Description | Applications |

|---|---|---|

| Speed | Can produce up to 120 packages per minute | Food packaging, pharmaceutical packaging |

| Versatility | Suitable for various bag sizes and shapes | Snack foods, granular products, liquids |

| Automation | Fully automated systems for efficient production | Mass production in factories |

| Material Compatibility | Compatible with plastic, paper, and laminated films | Coffee, spices, pet food |

| Ease of Use | User-friendly interface for operators | Small to large scale packaging operations |

Key Benefits: Why Invest in High-Quality Form Fill Seal Machines?

Investing in high-quality form fill seal machines offers numerous benefits that can significantly enhance productivity and efficiency in packaging operations. These machines are essential for industries ranging from food and beverages to pharmaceuticals, as they streamline the packaging process by combining forming, filling, and sealing into one automated system. This integration not only reduces labor costs but also minimizes the risk of contamination and material waste, leading to considerable cost savings over time.

According to industry reports, the packaging machinery market is projected to showcase a CAGR of over 4.5% from 2025 to 2032, indicating a robust growth trajectory. As businesses increasingly recognize the importance of efficient and reliable packaging solutions, the demand for high-quality form fill seal machines is set to rise significantly. Additionally, the market is anticipated to surpass USD 69.58 billion by 2032, highlighting the critical role that advanced packaging technologies play in meeting consumer demands and enhancing operational capabilities. By investing in top-tier form fill seal machines, companies can position themselves competitively in a rapidly evolving market landscape.

Exploring Different Types of Form Fill Seal Machines and Their Uses

Form fill seal (FFS) machines have become an integral part of the packaging industry, providing a streamlined solution for companies looking to enhance productivity and efficiency. According to a report by MarketsandMarkets, the global form fill seal market is projected to reach USD 6.9 billion by 2026, growing at a CAGR of 5.7% from 2021. This growth can be attributed to the increasing demand for packaged food and beverages, as businesses seek faster and more cost-effective packaging solutions. There are various types of FFS machines, including horizontal and vertical configurations, each designed for specific applications such as liquid, powder, or solid products.

Vertical Form Fill Seal (VFFS) machines are particularly popular in the food sector, as they efficiently package items ranging from powdered sugar to granola. Utilizing a continuous motion process, these machines can produce up to 150 packages per minute, minimizing downtime and labor costs. Conversely, Horizontal Form Fill Seal (HFFS) machines are well-suited for products requiring more complex packaging, such as ready-to-eat meals and multi-pack configurations. According to a study published by Research and Markets, the demand for HFFS machines is anticipated to increase by 6.2% annually, driven by the trend toward automated and flexible manufacturing systems capable of handling diverse product ranges.

As industries continue to innovate, the applications of form fill seal machines are expanding, making them a critical component in achieving efficient production lines and meeting consumer needs in a rapidly evolving market.

Enhanced Efficiency: How Form Fill Seal Machines Improve Production Speed

Form fill seal machines have revolutionized the packaging industry by significantly enhancing production efficiency. These advanced systems automate the entire process of forming, filling, and sealing packages, drastically reducing the time and labor involved in manual packaging methods. By minimizing human intervention, manufacturers can achieve faster turnaround times while ensuring consistent quality in their packaging, which is crucial for maintaining brand integrity.

One of the standout features of form fill seal machines is their versatility. They can handle a wide variety of products, ranging from liquids to solids, making them suitable for numerous applications across different industries, such as food and beverage, pharmaceuticals, and consumer goods. This adaptability not only boosts efficiency but also allows companies to pivot and respond quickly to changing market demands. With the integration of smart technology, these machines further optimize production speed by allowing real-time monitoring and adjustments, ensuring a smooth and uninterrupted packaging process.

Versatile Applications: Industries That Rely on Form Fill Seal Technology

The form-fill-seal (FFS) technology has become increasingly indispensable across various industries, particularly in food and beverage, pharmaceuticals, and consumer goods. The global market for form-fill-seal machines is anticipated to surge from USD 7.78 billion in 2025 to an impressive USD 13.86 billion by 2034, reflecting a growing demand for efficient and versatile packaging solutions. This trend is driven by the need for shorter changeovers and the ability to produce a wide variety of packaging formats to cater to consumer preferences. As the market evolves, FFS machines are innovating with technology that enhances operational flexibility and minimizes downtime.

Industries such as food and pharmaceuticals are finding tremendous value in sachet packaging machines, which are gaining traction due to their ability to streamline production and improve sanitation processes. The versatility of modern FFS machines allows for the integration of collaborative robots in palletizing and sealing tasks, offering heightened efficiency in high-mix/low-volume production environments. Furthermore, the advent of new filling equipment, alongside innovations like pre-zippered films, underscores the industry's commitment to meeting diverse customer needs while ensuring high standards of hygiene. As consumer expectations soar, brands are compelled to adapt by providing multiple packaging choices, reinforcing the essential role of form-fill-seal technology in today’s packaging landscape.