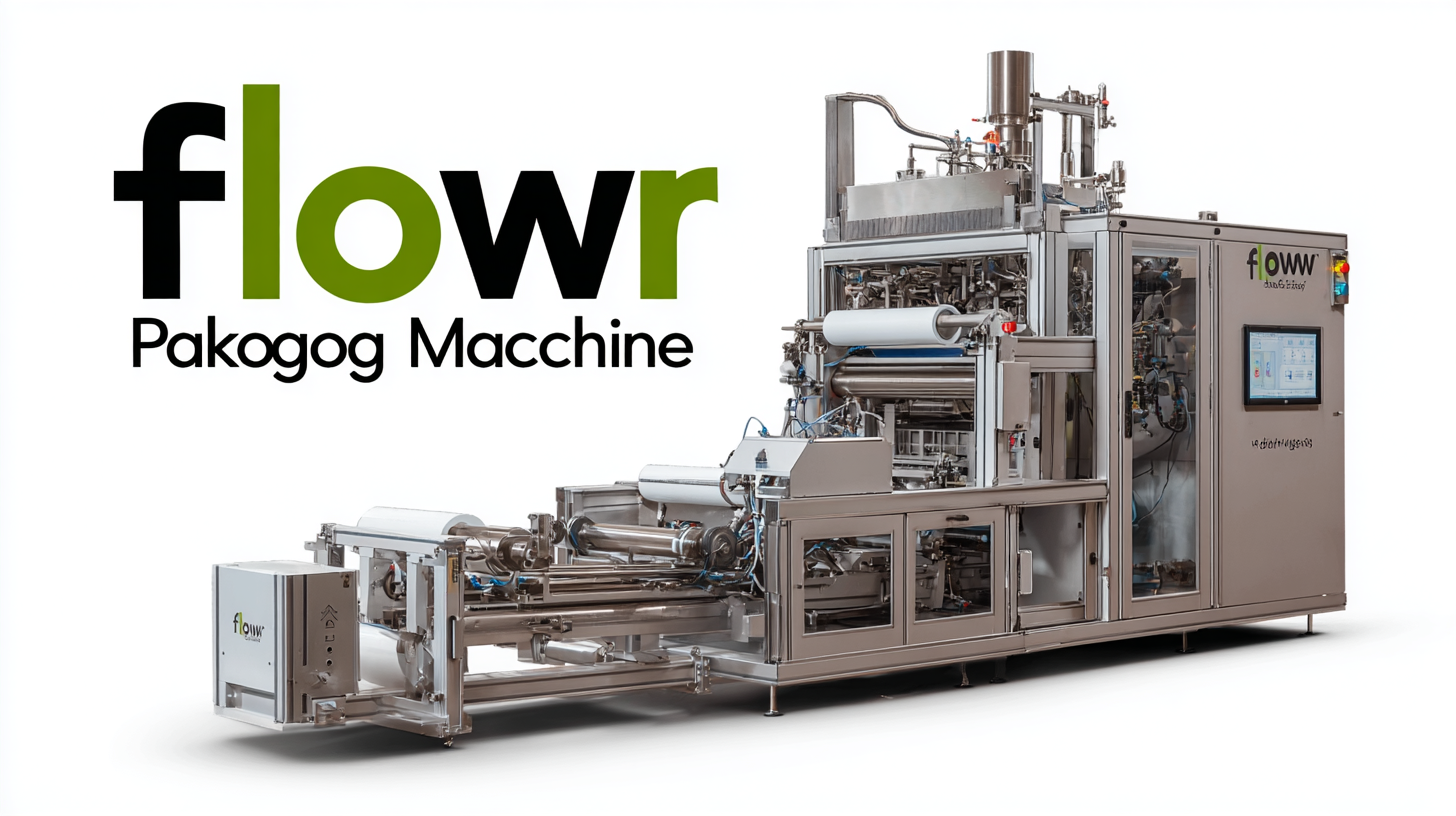

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

In the fast-paced world of packaging, the demand for efficient and reliable solutions has led to the proliferation of various technologies. Among these, the flow wrapper packaging machine has emerged as a cornerstone for businesses seeking to optimize their packaging processes. This innovative equipment allows for the seamless wrapping of products ranging from snacks to medical devices, ensuring durability and freshness. However, as industry needs evolve, so too does the exploration of alternative packaging methods that can potentially enhance productivity, sustainability, and cost-effectiveness. In this blog, we will delve into the landscape of flow wrapper packaging machines and examine some innovative alternatives that could redefine how products are packaged, while also discussing their unique features, benefits, and applications in diverse sectors. Join us on this journey as we uncover the future of packaging technology.

Understanding the Importance of Quality in Flow Wrapper Packaging

In the realm of flow wrapper packaging, understanding the importance of quality is paramount. Quality packaging is fundamental not only for preserving the integrity of food products but also for ensuring consumer safety. The seal area of flexible packages, often the most problematic aspect, plays a crucial role in controlling moisture and gas ingress. This directly affects the shelf life and overall quality of the packaged food. Manufacturers must therefore prioritize the advancement of sealing technologies to enhance the performance and reliability of flow wrappers.

Moreover, the evolution of packaging materials has led to improved functionality and sustainability. Recent developments in film technology have demonstrated significant potential for enhancing the effectiveness of flow wraps, particularly in the food industry. For example, innovations in packaging films designed specifically for ice cream have undergone rigorous testing to ensure they meet both quality standards and consumer expectations. This shift towards high-quality, functional materials not only boosts product appeal but also aligns with evolving consumer perceptions regarding safety and environmental responsibility. As the market continues to innovate, the synergy between packaging quality and consumer satisfaction remains a focal point in the industry.

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines - Understanding the Importance of Quality in Flow Wrapper Packaging

| Feature | Standard Flow Wrapper | Innovative Alternative |

|---|---|---|

| Speed (products/minute) | 60 | 80 |

| Packaging Material Type | Standard Film | Biodegradable Film |

| Energy Consumption (kWh) | 2.5 | 1.5 |

| Changeover Time (minutes) | 30 | 15 |

| Control System | Manual | Smart Automation |

| Maintenance Frequency (monthly) | 2 | 1 |

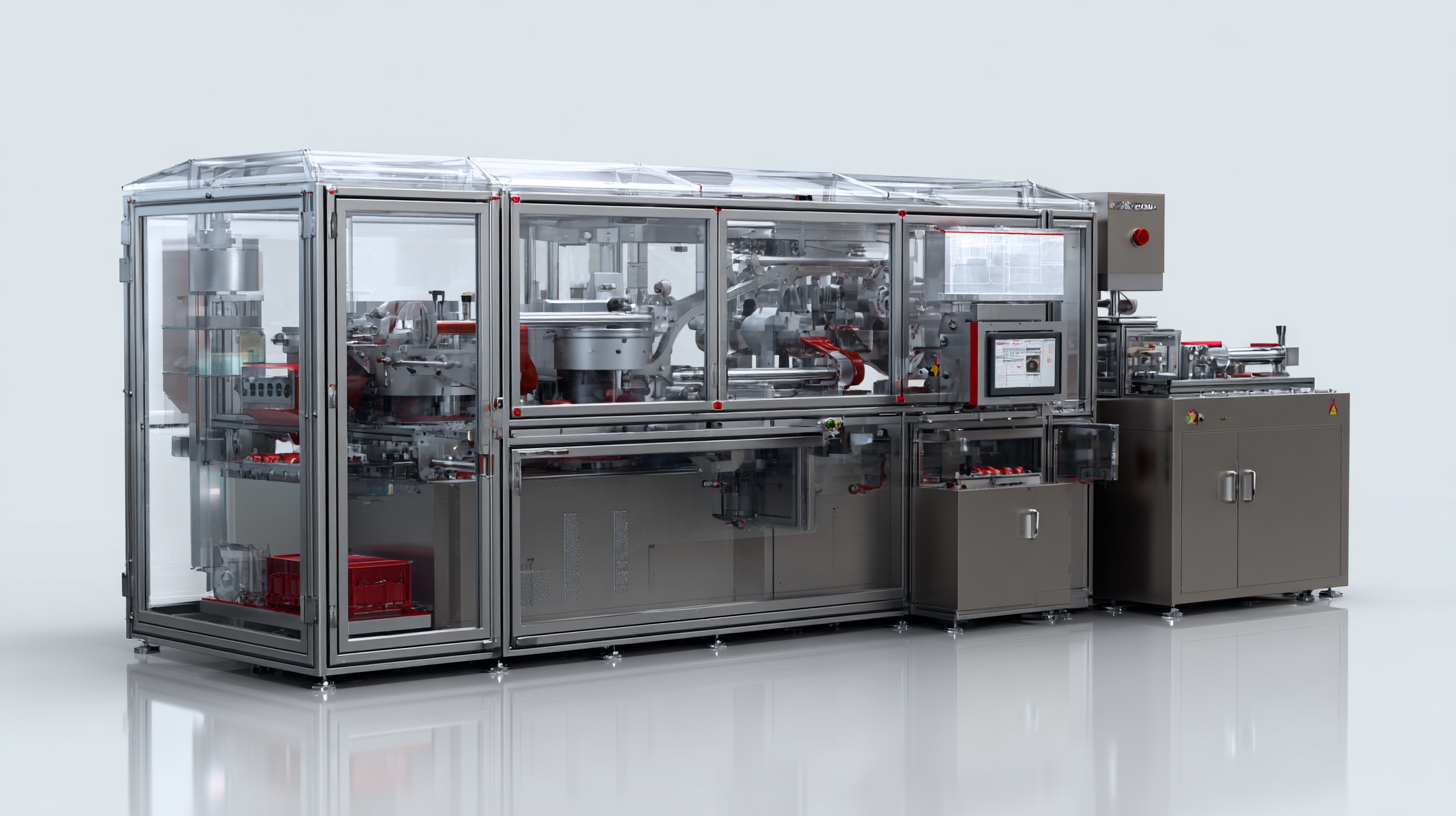

Evaluating Key Features of Flow Wrapper Packaging Machines

In the landscape of packaging technology, flow wrapper machines stand out for their efficiency and adaptability in packaging various products. The latest upgrades have introduced features that enhance user experience, flexibility, and automation, allowing businesses to meet diverse packaging needs with ease. Evaluating the key features of these machines helps manufacturers identify the right equipment that maximizes productivity while ensuring high-quality output.

When assessing flow wrapping machines, consider the importance of seal integrity, especially in the food industry. Understanding the mechanisms of heat sealing and the challenges associated with flexible food packaging can significantly impact the quality and shelf life of packaged goods. It's crucial to choose machines that offer customizable sealing options and advanced control systems for optimal performance.

Tips:

- Always prioritize machines that offer easy maintenance and automation, as they can reduce downtime and operational costs.

- Look for machines with advanced sealing technologies to ensure product freshness and minimize wastage.

- Evaluate the machine’s adaptability for various products; flexibility can offer a competitive edge in meeting changing market demands.

Identifying Reliable Suppliers in the Packaging Industry

In the quest for optimal packaging solutions, identifying reliable suppliers in the packaging industry is paramount. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2024, highlighting the increasing demand for innovative solutions like flow wrapper machines. As companies seek to enhance efficiency and sustainability, choosing suppliers who not only provide high-quality equipment but also prioritize technological advancements becomes essential.

To navigate this landscape effectively, companies should focus on suppliers with a proven track record of innovation and customer service. A recent industry survey indicated that 69% of businesses consider supplier reliability as a key factor when selecting packaging partners. Additionally, certifications and compliance with industry standards, such as ISO 9001, can act as indicators of a supplier's commitment to quality and sustainability. By thoroughly vetting potential suppliers, businesses can ensure they partner with those who are not only leaders in technology but also committed to providing consistent service and support in this rapidly evolving market.

Innovative Alternatives in Packaging Technology

This chart illustrates the adoption rates of various innovative flow wrapper packaging technologies over the past five years. The data highlights the increasing interest in sustainable materials and automation in the packaging industry.

Comparing Innovative Alternatives to Traditional Flow Wrappers

As businesses seek sustainable packaging solutions, innovative alternatives to traditional flow wrappers are gaining traction. Traditional options, such as plastic film and foil, while effective, contribute significantly to environmental waste. Recent developments highlight new materials that offer comparable performance while reducing ecological impact. For instance, the emergence of coated, heat-sealable paper-wrap materials presents a viable substitute. These innovative alternatives not only maintain high-barrier properties essential for preserving product freshness but also boast recyclability, making them an attractive option for eco-conscious companies.

When comparing these alternatives to traditional flow wrappers, it's crucial to assess their effectiveness in real-world applications. Studies in other fields, such as water treatment, have shown that alternative materials can perform as well as traditional ones, leading to a re-evaluation of longstanding practices. The transition to more sustainable packaging solutions reflects a broader trend toward environmental responsibility, encouraging industries to rethink packaging conventions in favor of more efficient and less harmful options. The adaptability and functionality of these new materials might just revolutionize the way products are packaged and presented in the market.

Building Long-Term Relationships with Your Packaging Suppliers

Building strong, long-term relationships with your packaging suppliers can significantly enhance your business operations and product quality. A reliable supplier doesn’t just provide materials; they become a strategic partner in innovation. Collaboration fosters open communication, allowing both parties to share insights and explore innovative alternatives to traditional flow wrapping methods. This ongoing dialogue can lead to tailored solutions that meet your specific packaging needs while also driving down costs.

One effective tip for nurturing these relationships is to engage in regular feedback sessions. This encourages transparency and helps suppliers understand your evolving requirements. Additionally, consider involving them early in your product development process. By seeking their expertise from the outset, you can incorporate their insights into design and material choices, leading to optimal packaging solutions.

Another important aspect is to invest in building trust. Acknowledge their contributions and show appreciation for their efforts. Consider setting up joint training programs or workshops to enhance both your team and your supplier's skills, fostering a culture of continuous improvement. This mutual investment will not only strengthen your relationship but also pave the way for innovative partnerships that can elevate your packaging solutions.