Discover Excellence in Manufacturing with the Leading Horizontal Packaging Machine from Top Chinese Factory

The global packaging machinery market is witnessing substantial growth, driven by the increasing demand for efficient packaging solutions across various industries. According to a report by MarketsandMarkets, the packaging machinery market is projected to reach $58.8 billion by 2026, expanding at a CAGR of 5.5%. Among these innovations, the horizontal packaging machine stands out as a versatile solution for manufacturers aiming to enhance productivity and streamline operations. Its ability to accommodate a wide range of products, from food items to pharmaceuticals, while ensuring precision and efficiency makes it a preferred choice for many top-tier manufacturers. This blog will explore industry-specific case studies showcasing the exceptional performance of horizontal packaging machines, along with practical guidance on their implementation and optimization in manufacturing processes.

Key Features to Look for in a Top Horizontal Packaging Machine

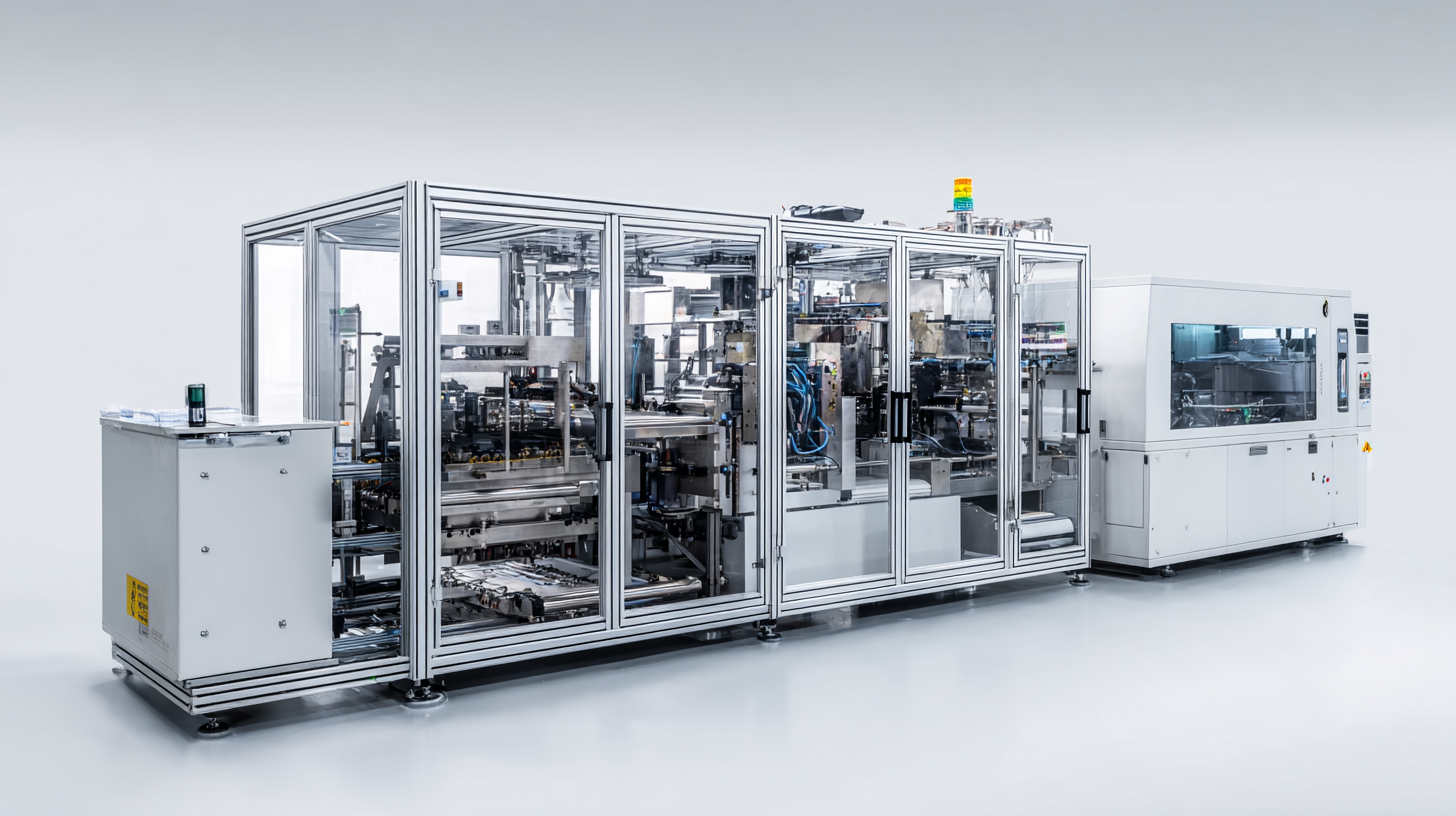

When selecting a horizontal packaging machine, there are several key features that can significantly enhance operational efficiency and product protection. First and foremost, look for machines equipped with advanced technology like servo-driven systems that provide high-speed packaging capabilities without compromising product integrity. This feature not only increases output but also ensures precision in packaging, crucial for maintaining quality control.

Another important aspect is the versatility of the machine. A top horizontal packaging machine should be adaptable to various product sizes and shapes, which is essential for businesses with diverse product lines. Additionally, consider machines that offer customizable packaging formats, allowing for flexibility in design and branding.

Lastly, ease of maintenance and user-friendly interfaces are crucial for minimizing downtime and ensuring smooth operation, making these features vital considerations in your search for the ideal packaging solution.

Essential Quality Standards in Manufacturing Horizontal Packaging Solutions

In the rapidly evolving landscape of manufacturing, quality standards play a pivotal role in ensuring the reliability and effectiveness of horizontal packaging solutions. The demand for packaging machines that not only meet but exceed industry standards is paramount. Manufacturers are increasingly seeking ways to incorporate rigorous quality control measures throughout their production processes. This is particularly significant in industries like pharmaceuticals, where product inspection and adherence to regulatory requirements are essential for safeguarding consumer health.

Innovations in technology have made it easier for manufacturers to achieve these essential quality standards. The integration of tech-enabled solutions allows companies to automate and enhance their quality assurance processes, ensuring that every package meets stringent criteria. This progression aligns with a broader trend where industries are re-evaluating their methods to embrace higher efficiency and safety in packaging. As manufacturers focus on these key quality standards, the commitment to excellence in packaging manufacturing becomes a defining characteristic of leading companies in the market.

Comparative Analysis: Leading Chinese Horizontal Packaging Machine Brands

The packaging machinery market is experiencing significant growth, with projections indicating a compound annual growth rate (CAGR) exceeding 4.5% from 2025 to 2032. As the industry approaches a valuation surpassing USD 69.58 billion by 2032, manufacturers are keen to adopt cutting-edge technologies to remain competitive. Among these advancements, horizontal packaging machines stand out, driving efficiency and versatility in production lines.

Leading Chinese brands in horizontal packaging machinery are at the forefront of this evolution. Their innovative designs cater to diverse sectors, including food and beverage, pharmaceuticals, and consumer goods. Within the dairy sector, for instance, the market for packaging machines is forecasted to grow at a robust CAGR of 5.1% until 2034, reflecting the rising demand for high-quality packaging solutions. The ability of these machines to offer precision, speed, and reliability is making them indispensable for manufacturers looking to enhance their operational capabilities and meet consumer expectations.

Discover Excellence in Manufacturing with the Leading Horizontal Packaging Machine

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Speed (Packages/min) | 120 | 150 | 130 |

| Packaging Type | Pillow | Flat | Stand-up |

| Power Consumption (kW) | 2.5 | 3.2 | 2.8 |

| Machine Dimensions (mm) | 2400 x 950 x 1600 | 2600 x 1000 x 1650 | 2500 x 900 x 1550 |

| Weight (kg) | 800 | 950 | 860 |

| Warranty (Years) | 2 | 2 | 3 |

Maintenance Tips for Ensuring Longevity of Your Packaging Equipment

Maintaining the longevity of your horizontal packaging machine is crucial for ensuring optimal performance and minimizing downtime. Regular maintenance practices can significantly extend the life of your equipment. One key aspect is routine cleaning; removing debris and product residue helps prevent malfunctions and keeps machinery running smoothly. It's essential to follow the manufacturer's guidelines for cleaning procedures and intervals, as neglecting this step can lead to larger problems down the line.

Another important tip is to conduct regular inspections of mechanical components. Check for wear and tear on belts, seals, and bearings, as well as any signs of misalignment. Early detection of these issues allows for timely repairs, reducing the risk of costly breakdowns. Lubrication should not be overlooked either; ensuring that all moving parts are properly lubricated can drastically reduce friction and wear, helping your packaging machine operate efficiently over time.

Furthermore, training your team on best practices for operating the packaging equipment is vital. Well-informed operators can spot potential issues before they escalate, leading to better maintenance outcomes. Investing in preventive measures not only enhances the performance of your horizontal packaging machine but also contributes to a more efficient manufacturing process overall.

Factors Influencing the Cost of Horizontal Packaging Machines in China

When considering the purchase of horizontal packaging machines from China, understanding the factors that influence their cost is essential for manufacturers aiming for excellence. A recent industry report indicates that the average cost of these machines can vary significantly, often ranging from $10,000 to $50,000, depending on features such as automation levels and production capacity. Advanced machines with greater automation tend to command higher prices due to their enhanced efficiency and reduced operational costs.

One major factor affecting pricing is the materials used in construction. Machines constructed from high-grade stainless steel are not only more durable but also offer better hygiene, which is crucial in sectors like food and pharmaceuticals. Additionally, technological advancements, such as smart sensors and integration with IoT systems, can increase initial investment but lead to long-term savings and efficiency improvements.

Tip: When evaluating different horizontal packaging machines, consider the total cost of ownership rather than just the upfront price. This includes maintenance, energy consumption, and potential downtime.

Tip: Always request detailed information about warranty periods and after-sales support from the manufacturer, as these factors can influence long-term satisfaction with your packaging solutions.