7 Effective Tips for Choosing the Right Food Packing Machine

In the rapidly evolving food industry, the choice of a food packing machine is crucial for ensuring product quality and operational efficiency. With the global market for food packaging projected to reach approximately $500 billion by 2025, according to a report by Grand View Research, selecting the right machine becomes paramount for businesses to stay competitive. Properly designed food packing machines not only enhance shelf life but also reduce waste, reflecting the increasing consumer demand for sustainable packaging solutions. As the sector becomes more technologically advanced, companies must consider factors such as automation, speed, and customization when choosing their food packing equipment. This blog provides seven effective tips to help you navigate the process of selecting the most suitable food packing machine for your specific needs and expectations.

Understanding Different Types of Food Packing Machines for Your Needs

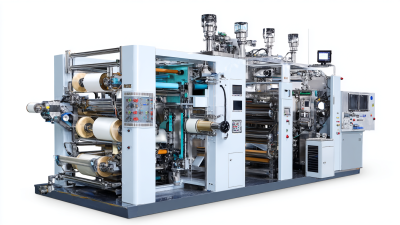

When it comes to selecting the right food packing machine, understanding the different types available is crucial to meeting your business needs. The food packaging machinery market is projected to grow from $45 billion in 2020 to over $60 billion by 2026, according to a recent industry report. This growth is driven by the increasing demand for packaged food products and advancements in packaging technologies.

One effective tip for choosing the right machine is to evaluate the type of product you're packaging. For instance, liquid packaging machines are specifically designed for beverages and sauces, while vacuum packing machines are ideal for preservation of meats and dry goods. Additionally, consider the packaging materials you intend to use—flexible films, rigid containers, or eco-friendly options—each requiring specialized machinery to optimize efficiency.

Another important consideration is the speed and scalability of the machine. According to a study by the Institute of Food Technologists, automation in packing can increase productivity by 30% or more without compromising quality. Therefore, selecting a machine that not only fits your current production needs but can also scale as your business grows can significantly enhance operational efficiency.

Key Factors to Consider When Selecting a Food Packing Machine

When selecting the right food packing machine, there are several key factors to consider that can significantly impact your efficiency and product quality. First, assess the type of food products you will be packaging. Different machines are designed for specific product types, whether you are dealing with liquids, solids, or powders. Understanding the nuances of your product will guide you towards the most suitable machine.

Another crucial tip is to evaluate the machine’s versatility. As the food packaging market evolves, innovations keep emerging, thus selecting a machine that can adapt to various packaging formats may provide long-term benefits. For example, consider whether the machine can handle different materials such as plastic, glass, or paper. Finally, think about the maintenance and support services offered by the manufacturer. A reliable service plan can help minimize downtime and ensure your operations run smoothly, ultimately contributing to the overall success of your packaging initiatives.

Comparing Automatic vs. Semi-Automatic Food Packing Solutions

When choosing the right food packing machine, one of the essential decisions centers around the type of automation to employ: automatic or semi-automatic solutions. Automatic machines are designed for high-volume production, featuring advanced technology that minimizes manual intervention, whereas semi-automatic machines strike a balance, allowing for human oversight while still offering some automation benefits. The global flexible packaging machinery market is projected to reach USD 13.7 billion by 2035, growing at a compound annual growth rate (CAGR) of 4.8%. This growth reflects the increasing demand for efficient packaging solutions across various food sectors.

For instance, the corrugated box making machine market, categorized by technology type into manual, semi-automatic, and automatic systems, is witnessing significant advancements. As per industry analysis, the trend leans strongly toward automatic machines, driven by the need for consistency and speed in production lines. Additionally, the wrapping machine market size is estimated to grow from USD 2.70 billion in 2024 to around USD 4.80 billion by 2034, indicating a robust evolution in packaging technologies. By evaluating these trends and market data, businesses can make informed decisions on whether an automatic or semi-automatic food packing machine best suits their operational needs and production goals.

Comparison of Automatic and Semi-Automatic Food Packing Machines

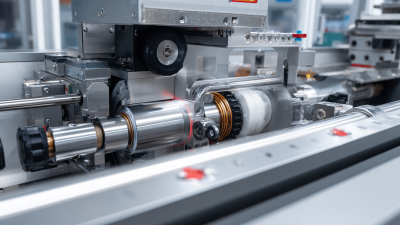

Evaluating the Latest Technology in Food Packaging Equipment

When evaluating the latest technology in food packaging equipment, it is essential to consider the rapid advancements that have transformed the industry in recent years. The global food packaging equipment market is projected to reach approximately $40 billion by 2027, growing at a CAGR of 4.5% from 2020. This growth is driven by increasing consumer demand for convenient, safe, and sustainable packaging solutions. Innovations such as smart packaging, which integrates sensors to monitor freshness, and automation technologies that streamline production processes are becoming standard in modern food packaging systems.

Moreover, sustainability plays a crucial role in the selection of food packing machines. According to a report by Smithers Pira, the sustainable packaging market is expected to reach $440 billion by 2025. This trend has prompted manufacturers to invest in eco-friendly materials and energy-efficient machines that reduce waste and environmental impact. Technologies such as biodegradable films and recyclable containers are crucial for businesses seeking to align with consumer preferences for sustainability. By staying abreast of these advancements, companies can not only enhance their operational efficiency but also meet the growing expectations for responsible food packaging.

Assessing the Cost vs. Benefits of Investing in Food Packing Machines

Investing in a food packing machine is a decision that can dramatically impact operational efficiency and product quality. When assessing the cost versus benefits, it is crucial to consider the long-term returns on investment. While the initial expenditure might appear daunting, the right machine can significantly reduce labor costs, minimize packaging wastage, and enhance packaging speed, ultimately leading to higher profitability. Businesses must also factor in the regulatory compliance and consistency in packaging quality that advanced machines provide, which can positively influence customer satisfaction and brand reputation.

Additionally, it's essential to evaluate the longevity and maintenance costs of the equipment. Some machines might require larger upfront costs but have lower operating costs over time due to more durable components and less frequent repairs. On the flip side, less expensive machines might involve recurring maintenance issues that could incur additional expenses. Therefore, a comprehensive analysis that weighs both the immediate costs and the potential long-term benefits will help businesses make informed decisions, ensuring they invest wisely in food packing solutions that align with their operational goals.

Related Posts

-

Innovative Solutions for Food Packaging Machine Efficiency and Quality

-

Ultimate Guide to Choosing the Best Packaging Machinery for Your Business

-

Top Strategies for Sourcing the Best Food Packing Machine Globally

-

Challenges in Meeting Industry Standards for the Best Horizontal Wrapping Machine

-

How to Choose the Right Food Packing Machine for Your Business Needs

-

How to Choose the Right Filling Machine for Your Production Needs