How to Choose the Right Horizontal Wrapping Machine for Your Business Needs

In today's highly competitive packaging industry, selecting the right equipment is crucial for enhancing productivity and maintaining product quality. A horizontal wrapping machine is often at the forefront of packaging solutions, providing versatility and efficiency across various sectors, including food, pharmaceuticals, and cosmetics. According to a recent industry report by Smithers Pira, the global packaging machinery market is projected to reach $50 billion by 2024, with horizontal wrapping machines playing a significant role in this growth due to their ability to accommodate diverse products and configurations. Furthermore, as consumer demand for speed and sustainability continues to rise, businesses must carefully evaluate their specific needs to optimize operations while minimizing waste. Understanding the capabilities and features of horizontal wrapping machines will empower companies to make informed decisions, ensuring their packaging processes meet the evolving market requirements.

Identify Your Packaging Requirements and Product Specifications

When selecting a horizontal wrapping machine for your business, it is crucial to first identify your packaging requirements and product specifications. Understanding the dimensions, weight, and shape of your products allows you to choose a machine that offers the right fit and functionality. For instance, if you are packaging beverages or food items, consider machines that can handle varying sizes and provide options for both eco-friendly materials and traditional plastic wraps.

Moreover, advancements in technology, such as the integration of RFID systems, can enhance your packaging process. These systems not only streamline logistics but also improve inventory management by enabling rapid data retrieval for tracking purposes. As consumer preferences evolve towards sustainable and transparent packaging solutions, ensuring that your chosen wrapping machine aligns with these trends is essential for maintaining a competitive edge in the marketplace. With these factors in mind, you can make an informed decision that meets both your operational needs and consumer expectations.

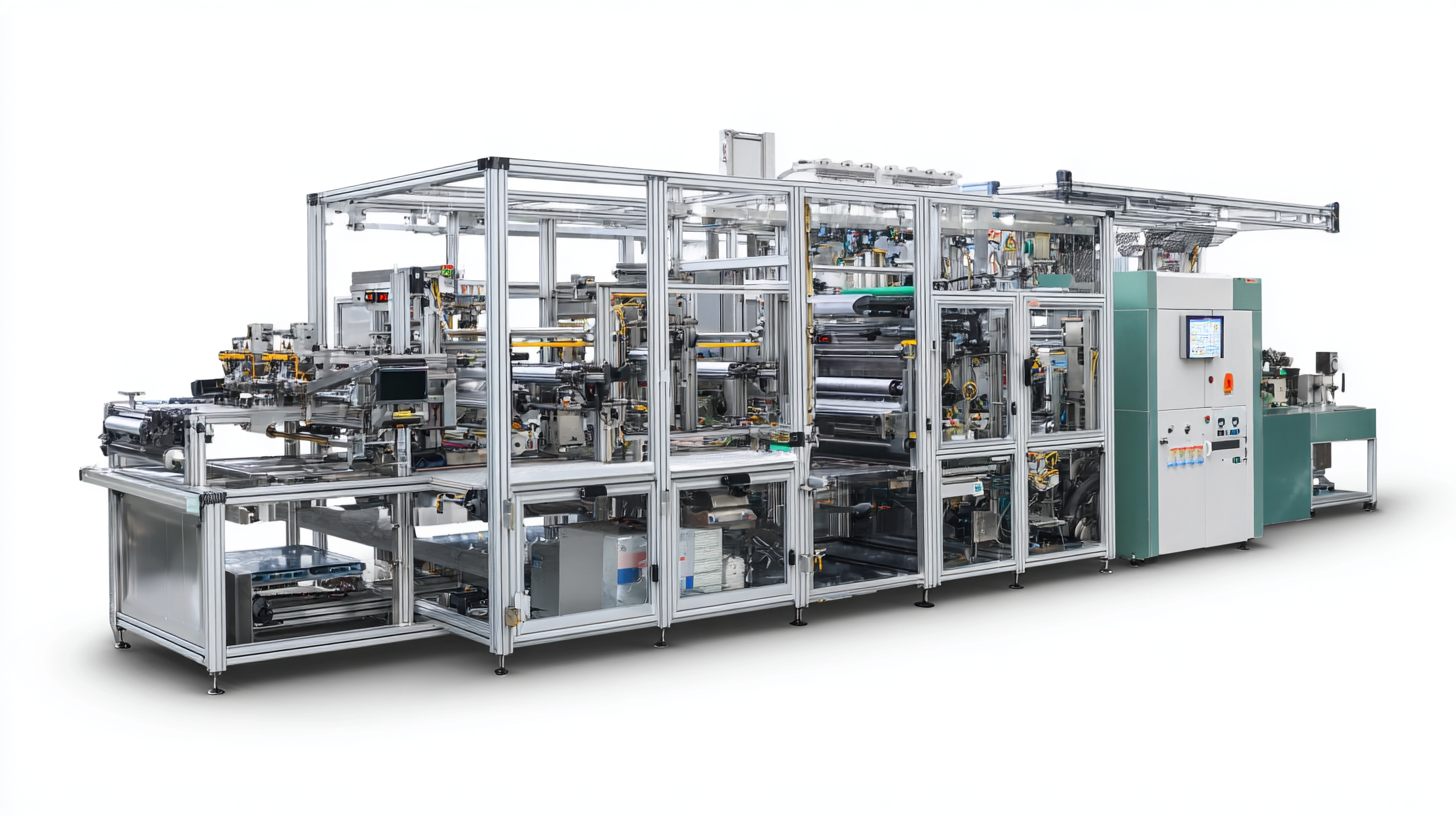

Evaluate Different Types of Horizontal Wrapping Machines

When evaluating different types of horizontal wrapping machines, it’s crucial to consider how each design caters to specific product shapes and sizes. According to a report by Smithers Pira, the global packaging machinery market is projected to grow by 3.9% annually, with a significant share attributed to horizontal wrappers, which are favored for their efficiency in accommodating a wide range of products, from candy bars to pharmaceuticals. These machines utilize a versatile wrapping process that enhances product protection while ensuring speed and accuracy.

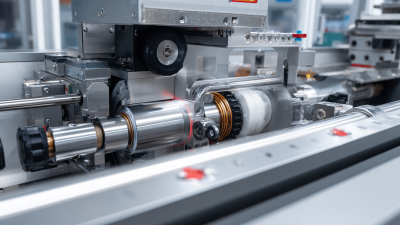

Another key factor to consider is the technology employed in these machines. Modern horizontal wrapping machines often come equipped with advanced features such as automatic film splicing and integrated quality control systems. A recent industry analysis by Grand View Research indicates that machines with such technological advancements can increase packing speeds up to 20% and significantly reduce material waste. Businesses must carefully assess these options based on their production demands, ensuring that the selected machine not only enhances operational efficiency but also aligns with product specifications and customer expectations.

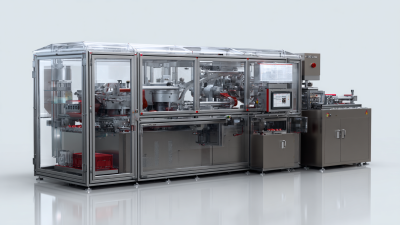

Consider Automation Levels and Efficiency Features

When selecting a horizontal wrapping machine for your business, the level of automation and efficiency features are critical factors to consider. Automated machines can significantly reduce labor costs and minimize the risk of human error, allowing your operations to run smoothly and efficiently. However, it's essential to assess your production needs; a fully automated system may not be necessary for smaller operations, while larger facilities might benefit greatly from such advancements.

**Tips:** When evaluating automation levels, consider how many products you need to wrap per hour and the complexity of the wrapping process. Look for machines that offer easy integration with existing production lines, ensuring that the workflow remains uninterrupted.

Efficiency features, such as adjustable speed controls and quick changeover capabilities, can greatly enhance productivity. A machine that allows for easy adjustments can accommodate various product sizes and types without significant downtime.

**Tips:** Investigate the machine's energy consumption and maintenance requirements as well. Opt for models that are energy-efficient and come with user-friendly maintenance schedules to minimize operational costs over time. Making informed decisions about automation and efficiency will lead to a more effective wrapping operation tailored to your specific business needs.

How to Choose the Right Horizontal Wrapping Machine for Your Business Needs - Consider Automation Levels and Efficiency Features

| Model | Automation Level | Efficiency Features | Speed (Packages/Min) | Suitable For |

|---|---|---|---|---|

| Model A | Fully Automatic | Sensor-Controlled, Automatic Film Feed | 30 | Food Packaging |

| Model B | Semi-Automatic | Adjustable Tension Control | 20 | Consumer Goods |

| Model C | Manual | Compact Design, Easy Film Replacement | 15 | Small Businesses |

| Model D | Fully Automatic | Real-Time Monitoring, High-Speed Operation | 40 | Pharmaceuticals |

Assess Budget Constraints and Total Cost of Ownership

When selecting the right horizontal wrapping machine for your business, understanding your budget constraints and the total cost of ownership is crucial. Initial purchase price is often a primary consideration, but it's essential to look beyond this and evaluate all associated costs. These include installation, maintenance, and the cost of consumables such as film and packing supplies. Taking the time to calculate these expenses can prevent unexpected financial burdens and help you make a well-informed decision.

Additionally, consider the longevity and reliability of the machinery. A machine that appears cheaper upfront may end up costing more in the long run if it requires frequent repairs or substitutes higher maintenance costs. Choosing a high-quality, durable machine can lead to reduced downtime, lower maintenance expenses, and improved productivity. Therefore, it’s not only about selecting a machine that fits your current budget but also one that aligns with your long-term financial strategy and operational needs.

Research Brand Reputation and Support Services for Equipment

When selecting a horizontal wrapping machine for your business, researching brand reputation and support services is crucial. According to a report by Smithers Pira on the packaging industry, companies that prioritize equipment reliability and manufacturer reputation consistently see a decrease in downtime. A reputable brand not only provides equipment with higher efficiency but also ensures access to quality customer support, which is essential for minimizing operational disruptions.

Furthermore, industry studies indicate that 70% of businesses find that robust support services improve their overall equipment performance. This includes prompt maintenance responses, availability of spare parts, and comprehensive training for staff. Brands with strong service networks, such as Aetna Group and Duravant, often receive higher customer satisfaction ratings. By thoroughly investigating reviews and performance metrics of potential brands, businesses can make informed decisions that align with their specific operational demands and ensure long-term success.

Related Posts

-

Discover World Class Manufacturing with the Best Flow Wrap Machine from China

-

How to Choose the Best Wrapping Machine by Understanding Key Technical Specifications and Features

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

-

Challenges in Meeting Industry Standards for the Best Horizontal Wrapping Machine

-

The Ultimate Guide to Choosing the Right Food Packaging Machine for Your Business Needs