How to Choose the Right Sachet Filling Machine for Your Business Needs

In today's competitive market, choosing the right sachet filling machine is crucial for businesses aiming to optimize their packaging processes and enhance operational efficiency. According to a recent report by Grand View Research, the global sachet packaging market is expected to reach USD 37.4 billion by 2025, growing at a CAGR of 6.1%. This growth underscores the increasing demand for flexible, efficient, and cost-effective packaging solutions across various industries, including food and beverage, pharmaceuticals, and personal care. Selecting the appropriate sachet filling machine not only improves product shelf life but also meets consumer expectations for convenience and sustainability. With a variety of machines available—each tailored for specific products and production needs—understanding your business requirements is paramount to making an informed investment that drives productivity and profitability.

Understanding Your Product Requirements for Sachet Filling

When selecting a sachet filling machine for your business, it's essential to understand your specific product requirements. The nature of your product—be it liquids, powders, or granules—will dictate the type of machinery you need. For instance, liquid products may require machines equipped with precision filling heads to ensure accurate dosages, while powders might necessitate auger fillers to handle flow rates effectively. Additionally, consideration of the product’s sensitivity to air and moisture can influence the design and functionality of the machine you choose.

The growing sachet packaging market, projected to increase significantly over the next decade, highlights the importance of investing in the right technology. As brands shift towards sustainability, awareness of materials used in sachets also plays a crucial role in decision-making. Companies are exploring options like smart packaging, which not only enhances product shelf life but also aligns with eco-friendly aspirations. Therefore, understanding the intersection of product requirements and emerging trends in packaging technology is vital for making an informed choice in the competitive landscape of sachet filling.

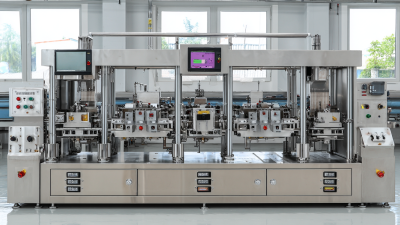

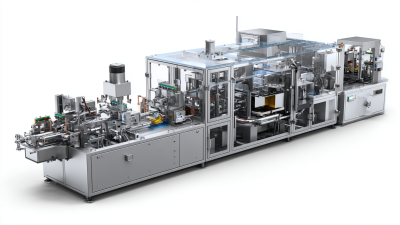

Evaluating Different Types of Sachet Filling Machines

When evaluating different types of sachet filling machines, it's essential to consider several key factors that align with your business's specific requirements. Sachet filling machines generally fall into two primary categories: vertical and horizontal configurations. According to a report by Grand View Research, the global sachet packaging market is expected to reach USD 30 billion by 2026, highlighting the increasing demand for efficient filling solutions.

Vertical machines are ideal for high-speed production lines and are commonly used for liquid products such as sauces and oils. In contrast, horizontal machines offer greater flexibility for packaging various product types, including powders and granules, making them suitable for businesses that require versatility.

Additionally, automation levels are crucial when selecting a sachet filling machine. A study by MarketsandMarkets indicates that automated filling machines can reduce labor costs by up to 30% and enhance production efficiency significantly. Businesses should assess their current production volumes and future growth projections to determine whether a semi-automated or fully automated machine is the best fit. Understanding these distinctions and incorporating industry data can lead companies to make informed decisions that optimize their packaging processes and cater to their business needs effectively.

Key Features to Look for in a Filling Machine

When selecting a sachet filling machine for your business, it’s crucial to consider key features that align with your operational needs. One of the foremost characteristics is the machine's speed and efficiency. According to a report by MarketsandMarkets, the sachet packaging market is projected to reach $15.2 billion by 2026, driven by efficiency in production lines. A suitable machine should provide adjustable filling speeds to accommodate varying production demands without compromising product quality.

Another vital feature is versatility in handling different products and sachet sizes. Machines that allow for quick changeovers between sachet formats can significantly reduce downtime. A European Packaging Study highlighted that companies utilizing multi-functional filling machines realized a 25% increase in overall productivity. Additionally, robustness and ease of maintenance are essential; machines built with durable materials not only withstand rigorous use but also reduce long-term operational costs. Choosing a filling machine that integrates these features can position your business for growth in an increasingly competitive market.

Key Features to Look for in a Sachet Filling Machine

Budget Considerations When Choosing a Filling Machine

When selecting a sachet filling machine, budget considerations play a crucial role in determining the best fit for your business. According to a market analysis by Technavio, the global sachet packaging market is projected to grow by 8% annually, indicating an increasing demand for efficient and cost-effective filling solutions. Businesses must assess their financial constraints against the potential return on investment (ROI) that a high-quality machine can deliver. Factors such as production speed, versatility, and maintenance costs should be analyzed to ensure alignment with financial goals.

Furthermore, the cost of filling machines can vary significantly based on features and capabilities. Basic models can range from $10,000 to $30,000, while high-end, automated systems can exceed $100,000. The International Packaging Association reports that companies investing in advanced filling technologies tend to gain a competitive edge through enhanced efficiency and reduced wastage. Balancing these costs with your production needs and market positioning is vital, as the right machine can lead to significant long-term savings and improved product quality.

Assessing Supplier Reputation and Support Services

When selecting a sachet filling machine, understanding the supplier's reputation and support services is crucial. A recent report by Grand View Research highlights that the global sachet packaging market is expected to reach $30.4 billion by 2027, driven by increasing consumer demand for convenience and efficient packaging solutions. With such a competitive landscape, choosing a supplier with a strong reputation can greatly influence your long-term success. Look for suppliers with positive customer reviews, industry certifications, and awards that showcase their reliability and commitment to quality.

Moreover, after-sales support is a critical factor. The same report indicates that machines requiring minimal downtime can significantly enhance productivity. Suppliers that offer robust support services, including training, maintenance, and quick access to parts, can effectively reduce operational disruptions. According to Packaging World, companies that invest in proper training and support service demonstrate a 30% increase in machine efficiency. Therefore, when assessing potential suppliers, prioritize those who provide comprehensive support packages to ensure your machine operates at peak performance, thereby safeguarding your investment and enhancing your business’s operational efficiency.

How to Choose the Right Sachet Filling Machine for Your Business Needs - Assessing Supplier Reputation and Support Services

| Criteria | Details | Importance Level |

|---|---|---|

| Supplier Reputation | Research supplier background, customer reviews, and industry experience. | High |

| Machine Specifications | Assess speed, capacity, and compatibility with packaging material. | High |

| After-Sales Support | Evaluate warranty, spare parts availability, and maintenance services. | Medium |

| Training and Installation | Check if supplier provides training and installation support. | Medium |

| Customization Options | Determine if the machine can be customized to your needs. | Low |

| Price | Compare pricing with features and evaluate cost-effectiveness. | High |

Related Posts

-

Choosing a Reliable Manufacturer for the Best Pouch Sealing Machines with Industry Insights

-

Exploring Cost Effective Alternatives to the Best Vertical Packaging Machine for Your Business

-

Exploring the Unique Features and Applications of the Best Form Fill Seal Machines: A Complete Guide

-

Common Challenges Faced by Buyers of the Best Automatic Packing Machine

-

Emerging Trends in Food Packaging Technology 2025 Your Ultimate Guide to the Best Food Packing Machines

-

7 Compelling Reasons Why Investing in a Pouch Filling Machine Can Boost Your Production Efficiency by 30%