Leading the World with Chinas Best Bag Filling Machine Innovation

In the competitive landscape of packaging machinery, the innovation of bag filling machines has emerged as a pivotal driver for efficiency and productivity in various industries. According to a recent report by MarketsandMarkets, the global market for bag filling machines is projected to grow from USD 2.1 billion in 2021 to USD 3.0 billion by 2026, reflecting an impressive CAGR of 7.5%. This growth trajectory highlights the increasing demand for automated solutions that enhance accuracy and speed in packaging processes. As companies worldwide seek to improve their operational capabilities, China's advancements in bag filling machine technology are setting new benchmarks in the industry.

By leveraging cutting-edge engineering and smart automation, these innovations not only optimize performance but also cater to the growing trend of sustainability in packaging. In this blog, we will explore the top strategies that position China as a leader in bag filling machine innovation, shaping the future of packaging solutions globally.

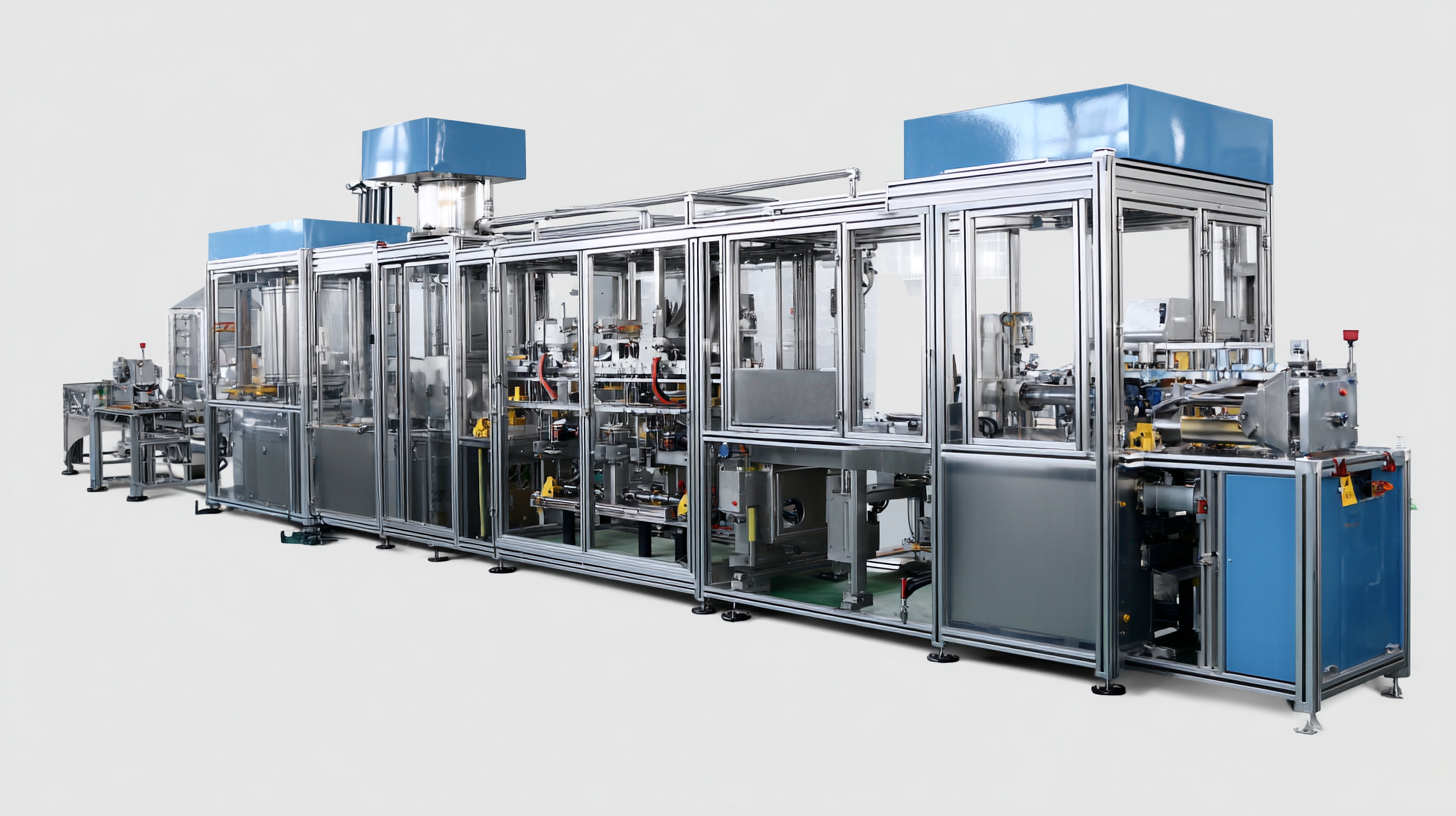

Revolutionizing Packaging: The Key Features of China's Cutting-Edge Bag Filling Machines

China's innovative bag filling machines are at the forefront of revolutionizing the packaging industry. These advanced systems integrate cutting-edge technology with user-friendly interfaces, allowing for seamless operation and high efficiency. One of the standout features includes precision filling, which ensures accurate dosage regardless of the product type, be it fine powders, granules, or liquids. This adaptability not only minimizes waste but also enhances the overall productivity of packaging lines.

Moreover, the machines boast enhanced automation capabilities, significantly reducing the need for manual labor. Equipped with advanced sensors and smart technology, they can detect product characteristics and adjust parameters accordingly, ensuring a consistent filling process. Additionally, the integration of real-time monitoring systems empowers manufacturers to oversee operations closely, facilitating timely maintenance and reducing downtime. As China leads the world in bag filling machine innovation, these key features not only optimize packaging efficiency but also drive the industry toward greater sustainability and performance.

Leading the World with China's Best Bag Filling Machine Innovation

Boosting Efficiency: How Innovation in Bag Filling Machines is Transforming Industries

In the rapidly evolving landscape of packaging, the integration of advanced technologies is setting a new standard for efficiency and sustainability. Innovations such as artificial intelligence (AI), the Internet of Things (IoT), blockchain, and robotics are at the forefront of this transformation. These technologies are not only streamlining operations, but they are also enabling companies to enhance their productivity. For instance, AI algorithms can predict maintenance needs and optimize filling processes, while IoT devices allow for real-time monitoring and data analysis, ensuring that businesses can respond swiftly to changes in demand.

As we look toward the future, emerging trends will further shape the packaging industry. The push for sustainable practices is leading manufacturers to embrace eco-friendly materials and reusable packaging solutions. Additionally, as automation technologies advance, robotic systems are becoming integral to production lines, reducing labor costs while increasing precision and speed. The packaging industry is on the cusp of a technological renaissance, and those who harness these innovations will not only bolster their operational efficiency but also contribute to a more sustainable and resilient future.

Top Tips for Choosing the Right Bag Filling Machine for Your Business Needs

When selecting the ideal bag filling machine for your business, understanding your unique needs is paramount. According to a recent industry report by MarketsandMarkets, the global bagging equipment market is expected to grow to $4.5 billion by 2026, showcasing the vast potential and competitive options available. Businesses must assess factors such as the type of product being packaged, the target production rate, and the desired level of automation. For example, companies dealing with bulk materials may benefit from gravity-fed filling systems, while precision filling for powders or granules might necessitate a more sophisticated auger or vacuum filling technology.

Additionally, your choice of bag filling machine should align with the specific bag types you plan to use. A study by Packaging Strategies notes that versatility in bag size and style can enhance operational efficiency. Machines designed to handle a variety of bag types—from stand-up pouches to flat bags—can reduce downtime and increase productivity. Furthermore, investing in a system that allows easy adjustments for different bag types can save your business valuable time and resources. By considering these critical factors, you can ensure that your investment in a bag filling machine meets your current needs and supports future growth.

Automation and Precision: The Role of Technology in Modern Bag Filling Solutions

In today's fast-paced manufacturing landscape, automation and precision stand at the forefront of advancement, particularly in the realm of bag filling solutions.

As industries evolve, the integration of technology transforms how products are filled and capped, significantly affecting shelf life and hygiene standards. Innovations in bag filling machinery now incorporate sophisticated filling and capping technologies, which not only extend the freshness of products but also ensure that safety protocols are strictly followed.

For companies looking to optimize their bag filling processes, consider implementing the following tips:

- First: Invest in automated systems that can track and adjust filling weights in real-time, ensuring consistency and reducing waste.

- Second: Explore advanced capping solutions that maintain sterility, as this will enhance product integrity and consumer trust.

- Finally: Regular maintenance and upgrades of your equipment can greatly increase efficiency and prevent disruptions in your production line.

These technological advancements illustrate the vital role of precision and automation in modern bag filling solutions, affirming the commitment to quality and safety in manufacturing.

Case Studies: Successful Implementation of China's Bag Filling Machines in Global Markets

China's bag filling machines have increasingly made their mark in global markets, showcasing a blend of innovation and efficiency. A recent report by Technavio reveals that the bag filling machine market is expected to grow by 5.6% by 2025, with China leading in terms of technological advancements and production capabilities. Successful case studies highlight how companies in various sectors have adopted these machines to improve productivity and reduce operational costs. For instance, a North American food manufacturer implemented China's high-speed bag filling technology, resulting in a 30% increase in packing efficiency and a significant reduction in material waste.

Tips: When considering bag filling machines, assess your production volume and product type. Selecting a machine specifically designed for your industry can maximize efficiency and align with your production goals. Partnering with experienced suppliers who offer comprehensive training and ongoing support can also enhance your operational success.

Another notable case study comes from a European cosmetics firm that integrated a Chinese bag filling machine into their packaging line. This transition not only streamlined their operations but also improved the overall aesthetics of their product packaging, leading to a 15% growth in sales within the first quarter post-implementation. As the global market for automated packaging solutions continues to expand, companies leveraging cutting-edge Chinese innovations are likely to stay ahead of the competition.

Tips: Evaluate the scalability of the bag filling machines as your business grows. Machines with modular designs can adapt to changing production needs, ensuring longevity and ROI. Regular maintenance and updates are also vital in keeping your equipment running optimally.