Challenges in Meeting Industry Standards for the Best Horizontal Wrapping Machine

As the packaging industry evolves, the demand for efficient and reliable horizontal wrapping machines has surged, driven by an increasing emphasis on product integrity and shelf-life extension. According to a recent market research report by Grand View Research, the global packaging machinery market is projected to reach USD 69.3 billion by 2025, with horizontal wrapping machines playing a pivotal role in this growth due to their versatility and efficiency in packaging various products. However, meeting industry standards presents a significant challenge for manufacturers looking to innovate while adhering to stringent regulatory requirements. The need for technological advancements that not only enhance performance but also comply with health and safety standards becomes imperative. This blog will explore the hurdles manufacturers face in optimizing horizontal wrapping machines while highlighting the anticipated technology trends for 2025 and the benefits of various types of wrapping solutions.

Understanding Industry Standards for Horizontal Wrapping Machines

Understanding industry standards for horizontal wrapping machines is crucial as manufacturers strive to meet the diverse demands from various sectors. The global wrapping machine market was valued at approximately USD 2.68 billion in 2024, and a growth rate of 5.9% CAGR is anticipated from 2025 to 2030. This growth signifies increasing reliance on advanced packaging technologies, especially in industries such as food and pharmaceuticals, where compliance with stringent health and safety regulations is paramount.

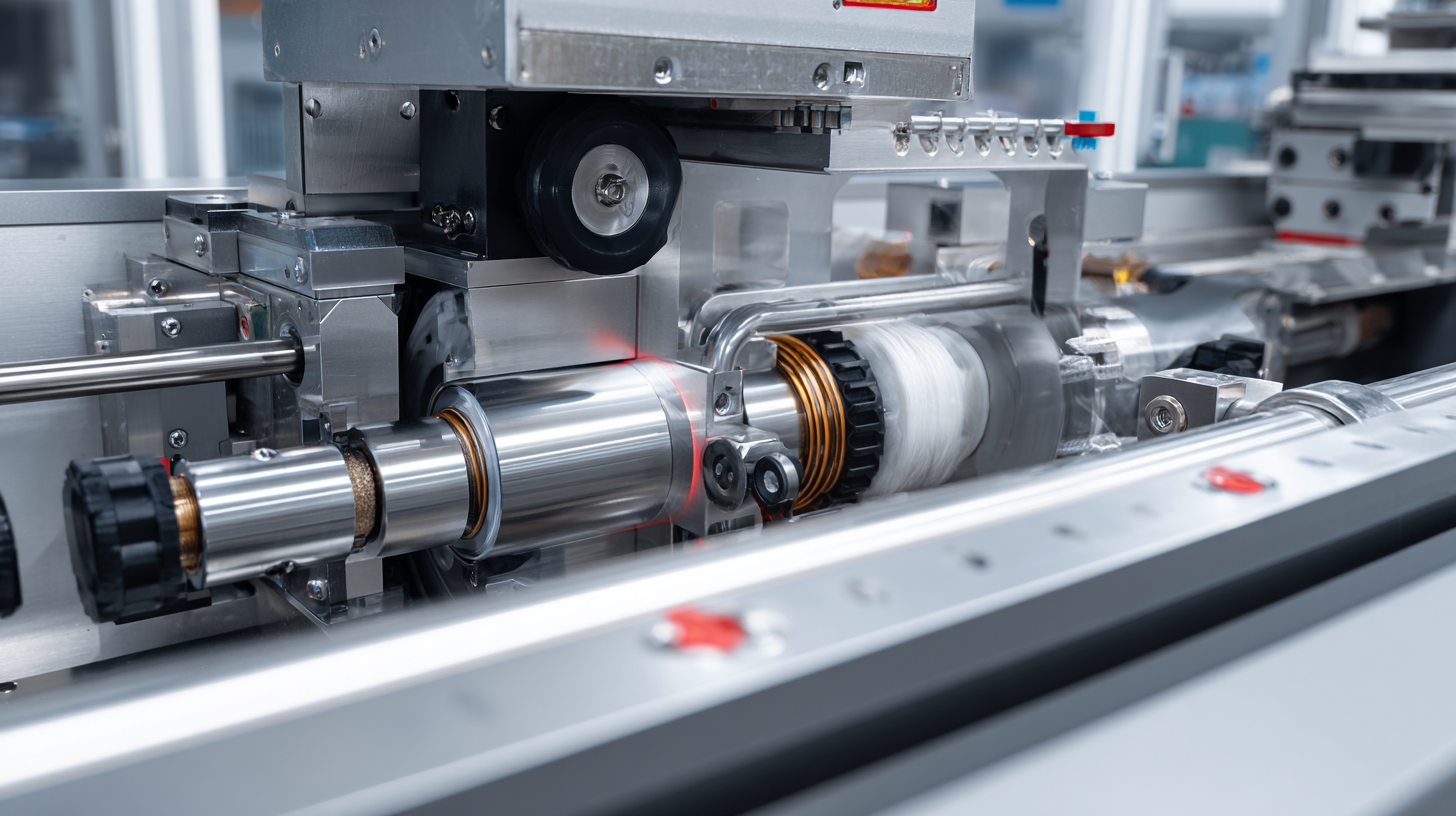

Manufacturers are constantly introducing innovative solutions to address these standards. For instance, the FM400 horizontal flow wrap machine has been designed to meet rigorous industry requirements, focusing on efficiency and versatility. Additionally, advancements in hygiene standards are becoming more significant; machines like the Washdown-360 vertical packaging system cater to environments that demand higher cleanliness. As these trends evolve, understanding and adapting to industry standards will be essential for businesses aiming to enhance their operational capabilities and maintain competitive advantages in the market.

Challenges in Meeting Industry Standards for the Best Horizontal Wrapping Machine

| Criteria | Industry Standard | Common Challenges | Impact on Production |

|---|---|---|---|

| Speed | Minimum 30 packages/min | Variability in product size | Reduced throughput |

| Material Compatibility | Compatible with multiple film types | Limited machine flexibility | Increased downtime for adjustments |

| Waste Reduction | Less than 5% waste | Inefficient wrapping techniques | Higher operational costs |

| Safety Standards | Compliance with OSHA guidelines | Inadequate safety features | Increased risk of workplace accidents |

| Automation Level | High level of automation expected | Technological limitations | Delayed production capacity |

Key Challenges in Compliance with Packaging Regulations

In the rapidly expanding field of sterilization medical packaging, compliance with stringent industry standards presents notable challenges. The market is projected to reach USD 14.2 billion by 2033, fueled by the rising demand for safe and sterile healthcare solutions. However, navigating the complex regulatory landscape can be daunting for manufacturers. Regulations often change, and packaging requirements must meet not only safety standards but also environmental considerations increasingly outlined in Extended Producer Responsibility (EPR) legislation.

To stay compliant, companies can implement a robust internal audit system, ensuring that all aspects of their operations align with current regulations. This proactive approach allows businesses to identify potential compliance gaps early and adjust their processes accordingly. Additionally, investing in smart packaging technology can enhance compliance and safety, particularly in an industry where traceability and information transparency are becoming prevalent.

As companies adapt to evolving legislation, embracing collaboration with regulatory experts can provide valuable insights and guidance. By staying informed about industry developments, including the implications of recent regulations in the US beauty sector and the new EU Critical Medicines Act, manufacturers can not only comply but also capitalize on emerging opportunities in the packaging market.

Technological Advancements Impacting Horizontal Wrapping Efficiency

Technological advancements are significantly reshaping the efficiency of horizontal wrapping machines, driven by innovations in smart packaging technologies. For instance, the emergence of RFID-based sensing has revolutionized the way product integrity is monitored during packaging, ensuring optimal conditions throughout the supply chain. These sensors can track humidity, temperature, and even gas composition, contributing to better product safety and freshness. As industries strive to meet stringent standards, the integration of such technologies into horizontal wrapping machines can streamline processes and enhance traceability, ultimately ensuring compliance with industry regulations.

Moreover, the advancement of microfluidic technologies is paving the way for more sophisticated packaging solutions. By revealing the mechanisms of horizontal gene transfer in various applications, these technologies can inspire new materials that enhance both the efficiency and sustainability of wrapping machines. As packaging methods evolve, manufacturers are focusing on minimizing waste and improving functionality, setting higher benchmarks in the sector. As we move forward, embracing these innovations will not only address regulatory challenges but also enhance operational effectiveness in the competitive landscape of packaging solutions.

Best Practices for Selecting a Horizontal Wrapping Machine

When selecting a horizontal wrapping machine, understanding the nuances of industry standards is essential for optimal performance and compliance. First, consider the specific needs of your production line. Evaluate the types of products being wrapped and their dimensions, as this will significantly influence the choice of machine. Additionally, the nature of the packaging material, whether it be plastic film, paperboard, or biodegradable options, must align with the machine's specifications. Identifying these factors early in the process can streamline decision-making and mitigate potential challenges.

Another critical aspect is the reliability of the manufacturer. It’s vital to choose a company with a solid reputation for producing durable and efficient machines that meet industry regulations. Look for suppliers that provide comprehensive after-sales support and readily available spare parts. Moreover, reviewing machine performance through case studies or client testimonials can offer insights into their effectiveness in real-world applications. By aligning your criteria with industry standards and best practices, you can ensure that the horizontal wrapping machine you choose not only meets current requirements but also future-proofs your operations.

Future Trends in Horizontal Wrapping Technology and Standards

In recent years, the horizontal wrapping technology has seen significant advancements driven by the need for eco-friendly packaging solutions. As China aims to enhance sustainability in its packaging industry, trends such as the shift towards green materials and the increasing production of specialty paper packaging are becoming prevalent. The regulatory framework surrounding food packaging is well-established, with around 500 standards ensuring safety and compliance. This development not only supports food safety but also encourages innovation in horizontal wrapping machines to meet these stringent requirements.

Moreover, the push for automation in food production, particularly in sectors like prepared meals, highlights the importance of integrating smart packaging solutions. Companies are focusing on developing customized packaging that can extend shelf life while maintaining product quality. As we look towards 2025, the packaging machinery sector is poised for growth, benefiting from government support and a strong market outlook. The convergence of technology and sustainability in horizontal wrapping is set to redefine industry standards, paving the way for a more efficient and responsible packaging future.