7 Top Benefits of the Best Form Fill Seal Machine for Global Buyers

In an era where global trade is thriving and manufacturers are under constant pressure to enhance efficiency, the form fill seal machine has emerged as a game-changer in the packaging industry. With its innovative technology and streamlined processes, this machine not only maximizes productivity but also ensures superior packaging quality, making it a pivotal asset for manufacturers aiming to compete on an international scale. As we delve into the top seven benefits of incorporating the best form fill seal machine in production lines, we celebrate the pride of Chinese manufacturing that meets global demands.

In an era where global trade is thriving and manufacturers are under constant pressure to enhance efficiency, the form fill seal machine has emerged as a game-changer in the packaging industry. With its innovative technology and streamlined processes, this machine not only maximizes productivity but also ensures superior packaging quality, making it a pivotal asset for manufacturers aiming to compete on an international scale. As we delve into the top seven benefits of incorporating the best form fill seal machine in production lines, we celebrate the pride of Chinese manufacturing that meets global demands.

From cost-effectiveness to versatility in packaging various products, these machines play a crucial role in building a robust supply chain and satisfying the needs of global buyers.

Join us as we explore how embracing cutting-edge packaging solutions can elevate your business to new heights in the competitive marketplace.

Key Features of the Best Form Fill Seal Machines for International Markets

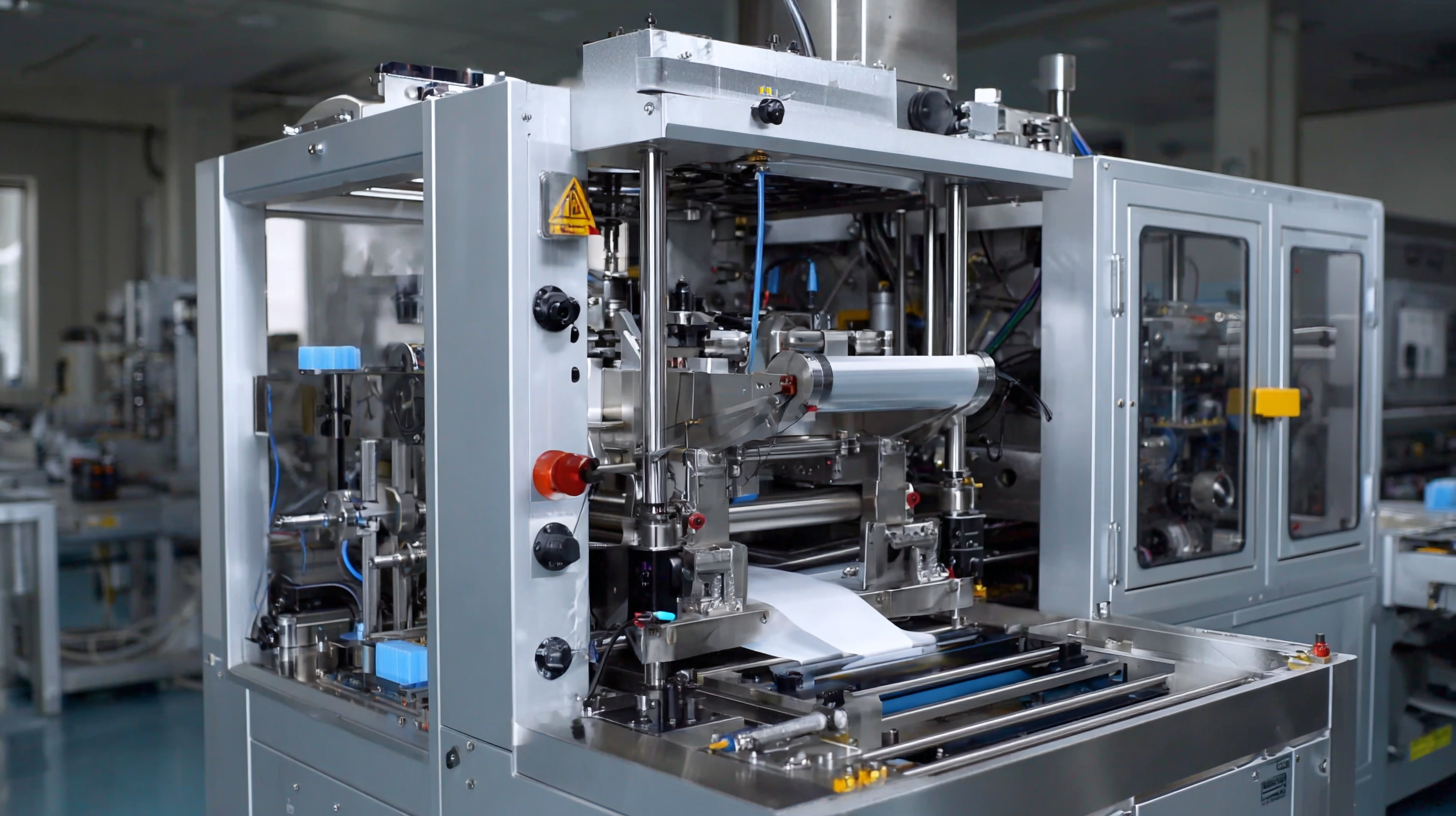

Form fill seal (FFS) machines have become indispensable in the packaging industry, especially for global buyers seeking efficiency and flexibility. Key features of the best FFS machines include high-speed operation, versatility in packaging types, and user-friendly automation. According to a report by MarketsandMarkets, the global form fill seal equipment market is projected to reach USD 5.9 billion by 2026, growing at a CAGR of 5.7% from 2021. This surge is driven by the need for faster packaging solutions while maintaining product quality.

Form fill seal (FFS) machines have become indispensable in the packaging industry, especially for global buyers seeking efficiency and flexibility. Key features of the best FFS machines include high-speed operation, versatility in packaging types, and user-friendly automation. According to a report by MarketsandMarkets, the global form fill seal equipment market is projected to reach USD 5.9 billion by 2026, growing at a CAGR of 5.7% from 2021. This surge is driven by the need for faster packaging solutions while maintaining product quality.

Additionally, advanced FFS machines are equipped with smart technology that enhances production efficiency. Integrated sensors and IoT capabilities allow for real-time monitoring and predictive maintenance, which significantly reduces downtime. A study by ResearchAndMarkets highlights that companies employing such intelligent systems have reported a 25% increase in operational efficiency. This combination of speed, adaptability, and innovation makes the best form fill seal machines a vital investment for businesses aiming to compete in international markets.

Understanding Export Certification for Form Fill Seal Machines

When it comes to purchasing form fill seal machines, understanding export certification is crucial for buyers aiming to ensure compliance with international standards. Export certification serves as a guarantee that the machinery meets specific regulatory requirements of the destination country, thereby facilitating smoother transactions and minimizing the risk of delays at customs. For global buyers, investing in certified machinery not only enhances credibility but also opens doors to new markets, as many countries require proof of compliance for safety and quality assurance.

Moreover, obtaining the necessary export certification can significantly impact the operational efficiency of manufacturers. Certified form fill seal machines often feature advanced technology that adheres to the latest industry standards, ensuring high performance and reliability. This not only boosts productivity but also fosters confidence among consumers regarding the quality of the final product. As competition intensifies in the global marketplace, understanding and navigating export certification becomes an essential part of the buying process, allowing businesses to stay ahead and expand their reach successfully.

How to Choose the Right Form Fill Seal Machine for Your Business Needs

When selecting the right form fill seal machine for your business needs, it's crucial to consider various factors that align with your production goals. Firstly, evaluate the type of products you plan to package. For instance, businesses dealing with fresh and cut products may require specific machinery designed to handle delicate items without compromising their quality. It's essential to choose machines that offer customization options to accommodate different packaging requirements effectively.

Additionally, automation plays a significant role in enhancing efficiency and productivity. The latest offerings in the market include advanced technologies that streamline the packaging process, reduce manual labor, and minimize waste. For instance, companies are now unveiling fully automated solutions that integrate filling systems, sealing mechanisms, and labeling features, enabling businesses to achieve higher output with precision. When assessing various machines, consider not only their technical specifications but also their ability to integrate seamlessly into your existing production line, ensuring a smooth workflow that meets your operational demands.

7 Top Benefits of the Best Form Fill Seal Machine for Global Buyers

| Benefit | Description | Importance for Global Buyers |

|---|---|---|

| Increased Efficiency | Automates the packaging process, reducing labor costs and time. | Allows faster production rates to meet global demand. |

| Reduced Material Waste | Optimizes film usage to minimize waste during production. | Lower costs and environmental impact attract eco-conscious buyers. |

| Versatility | Accommodates various product sizes and types. | Expands product offerings for international markets. |

| Consistent Quality | Ensures uniform packaging resulting in a professional appearance. | Strengthens brand image and customer trust worldwide. |

| Ease of Operation | User-friendly interfaces for quick training and setup. | Reduces downtime and increases adaptability for global teams. |

| Cost-Effective | Lower operational costs over time due to efficiency. | Enhances profit margins for competing in global markets. |

| Enhanced Safety Features | Incorporates safety mechanisms to protect operators. | Ensures compliance with international safety standards. |

The Role of Form Fill Seal Machines in Streamlining Production Processes

Form fill seal (FFS) machines play a crucial role in enhancing production efficiency, especially in sectors like food and beverage, pharmaceuticals, and consumer goods. According to a report by Research and Markets, the global FFS machine market is expected to reach USD 12.4 billion by 2027, growing at a CAGR of 4.1% from 2020. This growth is primarily driven by the increasing demand for automation in packaging processes, where FFS machines significantly reduce the production time and labor costs associated with packaging.

The streamlined workflow provided by form fill seal machines minimizes the risk of contamination and ensures consistency in packaging. The Food and Drug Administration (FDA) emphasizes the need for high hygiene standards in food packaging, which FFS machines meet through their integrated sealing processes. Moreover, FFS technology can adapt to various materials, such as plastic films and laminated materials, ensuring that manufacturers can tailor their packaging solutions to meet specific market demands. This adaptability not only optimizes the production process but also supports sustainability initiatives by reducing material waste and energy consumption throughout the packaging lifecycle.

Benefits of Compliance: Meeting Global Standards with Form Fill Seal Technology

The compliance benefits of using form fill seal (FFS) technology in

packaging are increasingly vital for global buyers. A 2023 report by Market Research Future highlights that the global

form fill seal market is projected to reach USD 6.09 billion by 2025, driven by the demand for improving operational

efficiency and ensuring product safety. FFS machines are engineered to adhere to stringent international standards, including

ISO and FDA regulations, which are crucial for companies aiming to tap into international markets.

By investing in advanced form fill seal technology, manufacturers can achieve better quality control and reduce contamination risks. According to a 2022 industry survey

conducted by the Packaging Machinery Manufacturers Institute (PMMI), 67% of companies

that implemented FFS technology reported a significant enhancement in product integrity and shelf life. This compliance not only mitigates the risk of product recalls

but also builds consumer trust, ultimately leading to increased market share. As regulations become more stringent globally, ensuring adherence to these standards with

FFS machines can provide a competitive advantage and position companies favorably in the ever-evolving marketplace.